In this modern era, Do You Think, a change can take place just by one day? The supply chain cycle has huge transformation within a week? A person can being the best leader of the world by one month? If your answers are “YES”, then come out from imagination.

In Black Swan Theory, Nassim Nicholas Taleb has pointed out Black Swan Event as an event that comes as a surprise, has a major effect, and is often inappropriately rationalized after the fact with the benefit of hindsight (Taleb, 2007).

Influenza Pandemic (1918-1920), Hong Kong Flu (1968-1970), Western African Ebola Virus Epidemic (2013-2015), Covid-19 Pandemic (2019- Present), etc. are the ‘Black Swan Events’ for the Supply Chain. During those period most of the supply chain managers were helpless and the business activities had collapsed alongside world recession. But always there something sparse that out of regular thinking; the manager who is the best have pledged his/her preparation by every action which help to stand solid in any circumstances.

The three D’s – Dimension, Deft, and Drive – are the prime areas that nowadays top supply chain managers have used to accelerate their organization and to have an eminent, efficient supply chain cycle which will also turn the Black Swan Events successfully.

1) Dimension

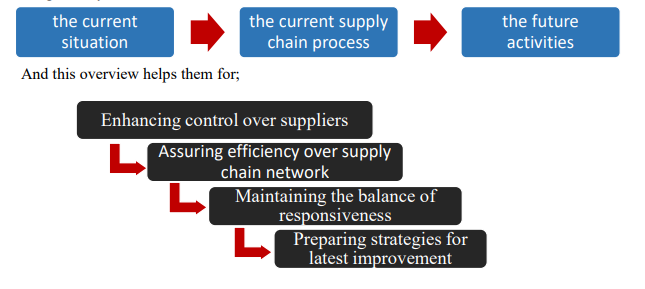

Dimension is about knowing own company’s supply chain’s functions, processes, strengths and weaknesses which yielded overall operation. This steps also creates awareness about the supply chain thinness and gives the idea to the supply chain managers about their flexibility.

Where British multinational consumer goods company “Unilever” and American

multinational consumers goods company “Procter & Gamble” always create an overview

of their supply chain activities after every action for baldness which drags them for

achieving their targets (unilever, 2021), (Gamble, 2021). They always mention three

things boldly at their overview;

2) Deft

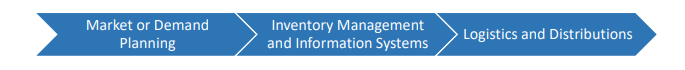

Deft is all about increasing productivity by using every factors and all forces perfectly that the organization has. For example, recently the Japanese multinational conglomerate corporation “Sony” is unable to fulfill their smartphone market’s demand because of their unsuccessfulness to execute and transform their abilities to enhance production & create variability (Corporation, 2021), where world’s two best smartphone manufacturing brand “Samsung” and “Apple” are creating distance with their opponents by satisfying their customers even in a Black Swan Situation like Covid-19 (Skool, 2021). And also “Samsung” & “Apple” puts evidence of their ability at supply chain by executing best practices in;

Organizations like “Microsoft”, “Google”, “Tencent” are also using this D for having a bridge role between Dimension and Drive (mentioned in point three) where it (Deft) has connected the supply chain process with the current & neo classical supply chain situations, moreover helps to identify and understand the risks what will arise. Meanwhile “Microsoft”, “Google”, “Tencent” are also using this step to have their preparation to square any Black Swan event (Microsoft, 2021), (Google, 2021), (Tencent, 2021).

3) Drive

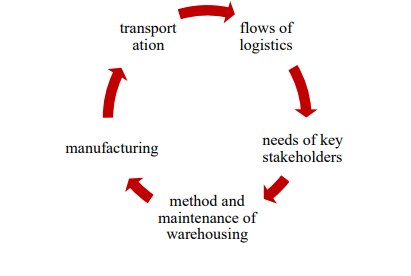

For driving the supply chain smoothly and for maintaining a proper internal environment within supply chain functions, Norwegian multinational telecommunications company “Telenor” & Malaysian multinational telecommunications company “Axiata” primarily carry the information about (Telenor, 2021), (Axiata, 2021);

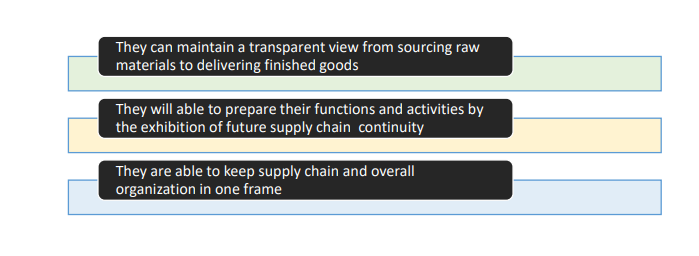

Basically those data and analysis facilitate the goal attainment process of “Telenor” & “Axiata” and make it easy to take any crucial decisions and understand the upcoming situation. Apart from that “Telenor” & “Axiata” also have other advantages, like;

Notion

Though our world is still suffering from Covid-19 Coronavirus, our daily activities aren’t stand still but have been done by other way and it is very much possible that pandemic like this will also can take place in our future time. So it is foolishness to a supply chain manager for waiting but not accommodate.

This is the place where three D’s at his best, because nowadays almost every proficient manager

is following and maintaining those steps, and if we have a quick look at their activities then we

will know that they are very much successful in their daily work and pandemic too.

To be frankly, in this uncertain modern world one supply chain manager not only will be successful by money and hardworking ability, but also will have to carry agility, proficiency and foresightedness and those matter the most.